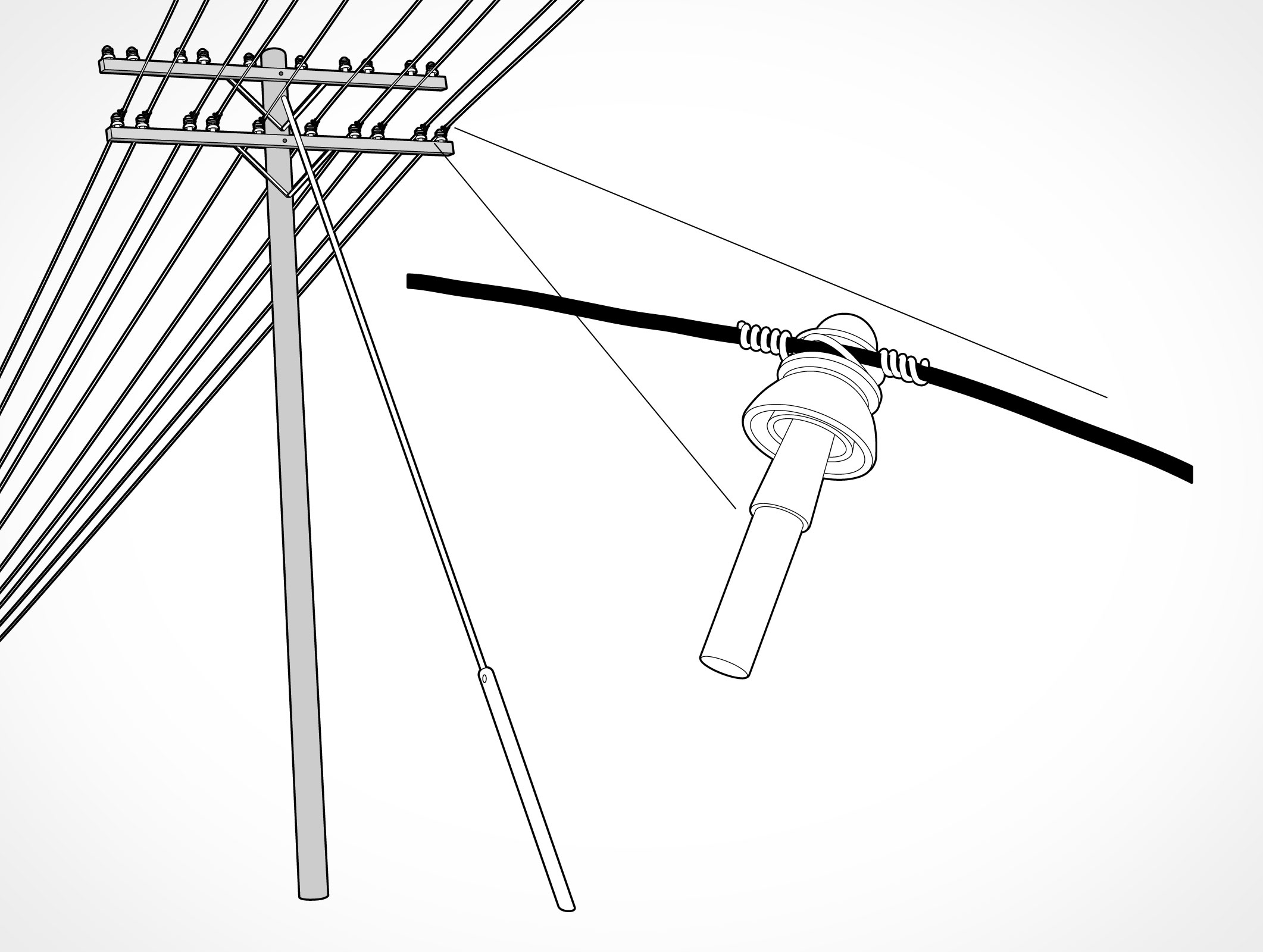

Guy wires are an indispensable component in the structural engineering and construction sectors, providing the necessary support and stability for various structures. These tensioned cables play a critical role in maintaining the upright position of tall structures such as towers, masts, and utility poles. By anchoring to the ground or another stable structure, guy wires counteract the forces exerted by wind, gravity, and other environmental factors, ensuring the safety and integrity of the supported structure. Without guy wires, many of the vertical structures we rely on daily would be at risk of collapse or instability.

Understanding the function and importance of guy wires is crucial for those involved in fields such as telecommunications, broadcasting, and electrical distribution. These industries often require the erection of tall structures that must withstand various environmental stresses. Guy wires provide the necessary mechanical support to these structures, allowing them to remain stable and operational regardless of external conditions. In addition to their practical applications, guy wires also have an aesthetic impact, contributing to the sleek and minimalist appearance of modern towers and poles.

In this comprehensive article, we will delve into the world of guy wires, exploring their history, design, and applications. We will discuss the different types of guy wires, their installation processes, and maintenance requirements. Additionally, we will examine the safety considerations associated with guy wires, as well as their environmental and economic benefits. By the end of this article, readers will have a thorough understanding of guy wires and their critical role in supporting modern infrastructure.

Table of Contents

- History of Guy Wires

- What Are the Different Types of Guy Wires?

- How Are Guy Wires Installed?

- Why Are Guy Wires Important?

- Safety Considerations

- Economic Benefits of Guy Wires

- Environmental Impact

- Guy Wire Maintenance

- Design Principles

- Applications in Different Sectors

- Future Developments

- Alternatives to Guy Wires

- Frequently Asked Questions

- Conclusion

History of Guy Wires

The concept of using tensioned cables to support structures dates back to ancient times, with early examples found in the construction of suspension bridges and other architectural marvels. Over the centuries, the materials and techniques used in guy wire construction have evolved significantly, driven by advancements in metallurgy and engineering. In the 19th century, the advent of steel cables marked a turning point in the use of guy wires, as they provided the strength and durability needed for increasingly ambitious architectural projects.

During the industrial revolution, the demand for telegraph and telephone lines led to the widespread use of guy wires to stabilize utility poles and towers. The development of radio and television broadcasting further increased the need for tall, stable structures, solidifying the role of guy wires in modern infrastructure. Today, guy wires are an essential component of numerous industries, providing the support required for everything from cellular towers to wind turbines.

What Are the Different Types of Guy Wires?

Guy wires come in various types, each designed to meet specific structural requirements and environmental conditions. The most common types include:

- Galvanized Steel Guy Wires: Made from high-strength steel, these wires are coated with a layer of zinc to prevent corrosion. They are widely used in outdoor applications due to their durability and resistance to the elements.

- Stainless Steel Guy Wires: Comprising a chromium-rich alloy, stainless steel guy wires offer excellent resistance to corrosion and are ideal for harsh environments, such as coastal areas or regions with high humidity.

- Kevlar Guy Wires: Known for their lightweight and high tensile strength, Kevlar guy wires are often used in applications where weight is a critical factor, such as in aviation or space exploration.

- Composite Guy Wires: Combining materials like fiberglass and carbon fiber, composite guy wires offer a balance of strength, weight, and flexibility. They are used in specialized applications that require unique performance characteristics.

Each type of guy wire has its advantages and limitations, and the choice of which to use depends on factors such as the structure's height, location, and environmental conditions.

How Are Guy Wires Installed?

The installation of guy wires is a critical process that requires careful planning and execution to ensure the stability and safety of the supported structure. The general steps involved in installing guy wires are as follows:

- Site Assessment: Before installation, a thorough evaluation of the site is conducted to determine the appropriate locations for anchoring the guy wires.

- Anchor Installation: Anchors are installed in the ground or attached to a stable structure to provide a secure point for the guy wires. The type of anchor used depends on the soil conditions and the load requirements of the structure.

- Wire Attachment: Guy wires are attached to the structure at specific points, typically near the top, and then connected to the anchors. The wires must be tensioned correctly to provide the necessary support.

- Alignment and Tensioning: The guy wires are aligned and tensioned to ensure even distribution of forces and to prevent sagging or slack. This step is crucial for maintaining the structure's stability.

- Inspection and Testing: Once installed, the guy wires are inspected and tested to verify their effectiveness and safety.

Proper installation of guy wires is essential for their performance and longevity, and it often involves collaboration between engineers, construction crews, and safety inspectors.

Why Are Guy Wires Important?

Guy wires are vital for maintaining the structural integrity and stability of tall, slender structures that are susceptible to bending or toppling due to environmental forces. Their importance can be attributed to several key factors:

- Wind Resistance: Guy wires help structures withstand strong winds by distributing the forces evenly and preventing excessive swaying or bending.

- Load Bearing: By providing additional support, guy wires enable structures to bear heavier loads, such as antennas or communication equipment.

- Cost Efficiency: Guy wires are a cost-effective solution for stabilizing tall structures without the need for extensive foundation work or reinforcement.

- Flexibility: The use of guy wires allows for greater flexibility in structural design, enabling the construction of taller and more slender structures.

In summary, guy wires play a crucial role in ensuring the safety, stability, and functionality of many essential structures, making them an indispensable component of modern infrastructure.

Safety Considerations

The use of guy wires involves several safety considerations to protect both the structures they support and the people who interact with them. Key safety aspects include:

- Proper Installation: Ensuring that guy wires are correctly installed, tensioned, and anchored is critical for preventing structural failure.

- Regular Inspections: Routine inspections help identify potential issues such as corrosion, wear, or damage, allowing for timely maintenance and repairs.

- Compliance with Regulations: Adhering to local and national safety standards and regulations is essential for ensuring the safe use of guy wires.

- Visibility Markers: In areas where guy wires pose a risk to aircraft or pedestrians, visibility markers or warning signs should be used to prevent accidents.

By addressing these safety considerations, the risks associated with guy wires can be minimized, ensuring the safety and reliability of the supported structures.

Economic Benefits of Guy Wires

Guy wires offer several economic advantages, making them a popular choice for supporting tall structures:

- Cost Savings: Compared to alternative support methods, guy wires are relatively inexpensive to install and maintain, reducing overall project costs.

- Material Efficiency: The use of guy wires allows for more efficient use of materials, enabling the construction of lighter and less resource-intensive structures.

- Reduced Construction Time: Guy wire installation is typically quicker and less labor-intensive than other support methods, shortening construction timelines.

These economic benefits make guy wires an attractive option for a wide range of industries, from telecommunications to renewable energy.

Environmental Impact

Guy wires have a relatively low environmental impact compared to other support structures. Their minimalistic design reduces the amount of materials required, resulting in less resource extraction and waste. Additionally, guy wires can be recycled or repurposed at the end of their lifespan, further minimizing their environmental footprint.

However, it's essential to consider potential environmental risks, such as the impact of guy wire installations on local ecosystems and wildlife. By conducting thorough environmental assessments and implementing mitigation measures, these risks can be effectively managed.

Guy Wire Maintenance

Regular maintenance is essential to ensure the continued performance and safety of guy wires. Key maintenance activities include:

- Inspection: Routine inspections should be conducted to check for signs of wear, corrosion, or damage.

- Tension Adjustment: Guy wires may require periodic tension adjustments to compensate for environmental changes or structural shifts.

- Corrosion Protection: Applying protective coatings or treatments can help prevent corrosion and extend the lifespan of guy wires.

By implementing a proactive maintenance program, the longevity and reliability of guy wires can be maximized.

Design Principles

The design of guy wires involves several key principles to ensure their effectiveness and safety:

- Load Analysis: Understanding the loads and forces acting on the structure is critical for determining the appropriate guy wire specifications.

- Anchor Placement: Proper placement and design of anchors are essential for providing the necessary support and stability.

- Tension Distribution: Ensuring even distribution of tension across the guy wires is crucial for preventing structural imbalances.

These design principles guide the selection, installation, and maintenance of guy wires, ensuring their optimal performance.

Applications in Different Sectors

Guy wires are used across various sectors due to their versatility and effectiveness. Key applications include:

- Telecommunications: Guy wires provide the necessary support for cellular towers, radio masts, and other communication infrastructure.

- Energy: In the energy sector, guy wires stabilize wind turbines, transmission lines, and other energy-related structures.

- Construction: Temporary guy wires are often used to support scaffolding and other temporary structures during construction projects.

The widespread use of guy wires across these sectors underscores their critical role in modern infrastructure.

Future Developments

As technology and engineering continue to evolve, new developments in guy wire materials and design are expected. Innovations such as advanced composite materials and smart monitoring systems may further enhance the performance and safety of guy wires, opening up new possibilities for their use in emerging industries and applications.

Alternatives to Guy Wires

While guy wires are a popular choice for structural support, alternative methods exist, including:

- Self-Supporting Structures: These structures rely on their own rigid design to remain stable, eliminating the need for guy wires.

- Monopoles: A single, sturdy pole provides support without the need for additional cables or anchors.

Each alternative has its advantages and limitations, and the choice depends on factors such as cost, design, and environmental considerations.

Frequently Asked Questions

What is a guy wire used for?

Guy wires are used to provide stability and support to tall, slender structures, preventing them from bending or toppling due to environmental forces like wind and gravity.

How often should guy wires be inspected?

Guy wires should be inspected regularly, typically every six months to a year, to check for signs of wear, corrosion, or damage and ensure their continued effectiveness.

Can guy wires be recycled?

Yes, guy wires can be recycled or repurposed at the end of their lifespan, reducing their environmental impact and contributing to sustainable practices.

What materials are commonly used for guy wires?

Common materials for guy wires include galvanized steel, stainless steel, Kevlar, and composite materials, each offering different advantages based on the application's requirements.

Are there any safety risks associated with guy wires?

While guy wires are generally safe, potential risks include improper installation, poor tensioning, and lack of visibility markers, which can lead to structural failure or accidents.

How do guy wires help with wind resistance?

Guy wires distribute wind forces evenly across the structure, preventing excessive swaying or bending, which helps maintain the structure's stability and integrity.

Conclusion

Guy wires are a vital component in the support and stability of modern infrastructure, providing the necessary mechanical support for a wide range of structures. Their cost-effectiveness, versatility, and reliability make them an essential tool in industries such as telecommunications, broadcasting, and energy. As technology and materials continue to advance, the role of guy wires is likely to expand, further cementing their importance in the world of structural engineering and construction. By understanding their applications, benefits, and maintenance requirements, we can ensure the continued success and safety of the structures they support.

Article Recommendations

- Unveiling The Details About Rudy Youngblood Wife A Comprehensive Insight

- Exploring Kannada Movierulzcom A Gateway To Kannada Cinema

- The Untold Story Of Thomas Beaudoin Accident What Really Happened